N.F.T. (Nutrient Film Technique) System

The

N.F.T. system (Nutrient Film Technique) is quite popular with

home hydroponic growers as well. Mainly because of it's fairly

simple design. However N.F.T. systems are best suited for, and

most commonly used for growing smaller quick growing plants like

different types of lettuce. Along with growing lettuce, some commercial

growers also grow different types of herbs and baby greens using

N.F.T. systems.

The

N.F.T. system (Nutrient Film Technique) is quite popular with

home hydroponic growers as well. Mainly because of it's fairly

simple design. However N.F.T. systems are best suited for, and

most commonly used for growing smaller quick growing plants like

different types of lettuce. Along with growing lettuce, some commercial

growers also grow different types of herbs and baby greens using

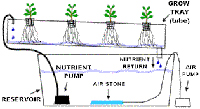

N.F.T. systems. While there are a lot of different ways design an N.F.T. system, they all have the same characteristic of a very shallow nutrient solution

cascading

downward through the tubing. Where the bare roots of the plants

come in contact with the water, and can absorb the nutrients from it.

The major downside to an N.F.T. systems is that the plants are very

sensitive to interruptions in the flow of water from power outages (or

whatever reason). The plants will begin to wilt very quickly any time

the water stops flowing through the system.

cascading

downward through the tubing. Where the bare roots of the plants

come in contact with the water, and can absorb the nutrients from it.

The major downside to an N.F.T. systems is that the plants are very

sensitive to interruptions in the flow of water from power outages (or

whatever reason). The plants will begin to wilt very quickly any time

the water stops flowing through the system. What you need to build a N.F.T. system:

- Container to hold the nutrient solution (a reservoir)

- Submersible fountain/pond pump

- Tubing to distribute water from the pump to the N.F.T. growing tubes

- Growing tubes for the plants to grow in (also called a gully/channel)

- starter cubes, or small baskets and growing media to start seedlings in

- Return system (tubing, channels) to guide the used nutrient solution back to the reservoir

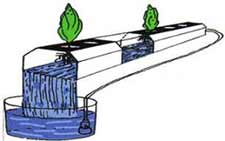

The plants in the growing tubes (channel/gully) are typically suspended above the water by placing seedlings started in starter cubes or small one inch baskets of growing media into small holes in the top of the tube. The roots of the seedlings hang down to the bottom of the tube/channel where they get nutrients from the shallow film of nutrient solution flowing by. The excess nutrient solution flowing out of the low end of each of the channels drains into another channel or tube, and guided back to the reservoir where it is recirculated through the system again.

While the nutrient solution flowing through the channels is very shallow, the entire plants root mass remains moist from the roots being able to wick up moisture on the outside of the roots, as well as through humidity that's kept within the tube/channel. The roots that are suspended between the base of the plant and the water level in the channel not only have moisture to access, but are also able to get plenty oxygen from the air surrounding them within the tube/channel as well.

Commercial growers typically use specially made channels/gully's for N.F.T. systems that have flat bottoms with grooves running lengthwise along the channel. These grooves allow water to flow underneath the root mass and help keep it from pooling or damming up. Home growers often use vinyl rain gutter down spouts for their channels. These vinyl down spouts have similar grooves, but cost just a fraction of what the commercially made channels/gully's cost. Home growers also often use round ADS (Advanced Drainage System) irrigation tubing for N.F.T. systems. The ADS tubing doesn't have grooves, but with increasing the slope to compensate, the round tubing works well also.

N.F.T. system Flow rate, and channel slope

How deep should the water be, and how fast should the water be flowing are the two most common questions asked about this type of system. First the slope of the channel controls how fast the water goes through the tube/channel (not the water pump or).

The recommended slope for a N.F.T. system is typically a 1:30 to 1:40 ratio. That is for every 30 to 40 inches of horizontal length, one inch of drop (slope) is recommended. We recommend when designing your N.F.T. systems, you design it so you can adjust the slope while the plants are still growing. That's because as the root systems get bigger, they may cause it to pool and dam up the water flow. If it's adjustable you can tilt it more to compensate if needed. Also when building your N.F.T. systems, try and keep the channels/gully's as true as possible. If they sag in spots, water will pool up in those areas.

The recommended flow rate for a N.F.T. system is typically between 1/4 gallon to 1/2 gallon per minute (1 to 2 liter's) for each grow tube (channel/gully). Or between 15 gallons to 30 gallons per hour (60 to 120 liter's). While the plants are just seedlings the recommended flow rate can be cut in half, and then increased as the plants get bigger. Flow rates much higher or lower than these have sometimes been associated with nutrient deficiencies. Also nutrient deficiencies have sometimes been seen when growing tubes (channel/gully) are longer than 30 to 40 feet (10 to 15 meters). However it's been shown that having a second nutrient feed line half way down the growing tube (channel/gully) eliminates that issue.