In Ground Geothermal Nutrient Reservoir

Geothermal Energy is free energy. Meaning the

exchange of heat that's provided by the earths soil, is free. In

hydroponics it's common to keep the nutrient reservoir underground, and

has been done for years to help keep the nutrients cool. In order to

get the full effects of Geothermal Energy there are a few things to

consider.

- There should be no air between the sidewall

of the reservoir and the ground. Air is an insulator and will insulate

the reservoir from the ground therefor insulating it from the

Geothermal Energy. Basically the heat wont be able to be extracted from

the reservoir into the ground efficiently.

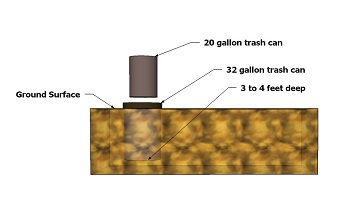

- For best effects it

should be at least 3 feet deep. The underground temperature of the

earth remains constant thought the year. The underground temperature is

insulated from the above ground temperatures by the Earth's crust.

Typically 3-5 feet is enough, although in places of permafrost, it

should be placed deeper than the deepest permafrost.

- Everything

above ground should be insulated to prevent the absorption of heat when

you pump the nutrient solution through the system. You don't want the

above ground tubing/piping that the nutrients are flowing through to

get hot and allowing the nutrients to heat up on its way to and from

the plants. That would defeat the purpose of keeping them underground

in the first place.

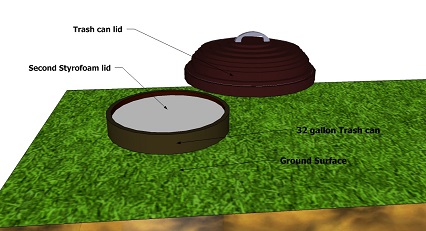

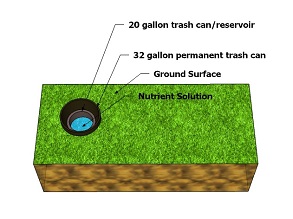

In ground Reservoir

With

hydroponics it is important to design things so they are easy to use

and easy to clean when needed. This is one example of a nutrient

reservoir that addresses the issues above, but allows for easy access

and cleaning.

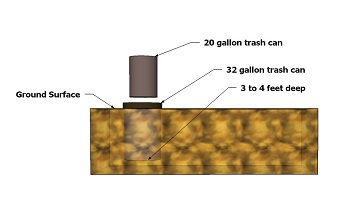

Dig

a hole large enough to to place a 32 gallon trash can in the ground at

least 3 feet deep. Fill in the sides around the 32 gallon trash can

with soil. This container/trash can will be permanently in the ground

and makes direct contact with the earth (no air gaps). The 20

gallon (smaller) trash can will sit inside the larger one and will be

the nutrient reservoir.

The

smaller 20 gallon container/trash can will allow you to easily take it

out for cleaning while leaving the larger container in direct

contact with the ground.

(Note: these container sizes are not

set in stone. The idea is to have one that is permanently in the

ground, and another one that will fit inside of it that can be easily

pulled out for maintenance.)

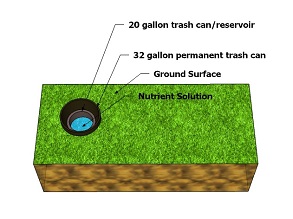

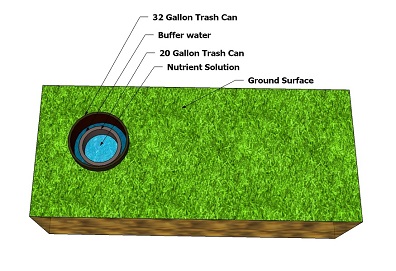

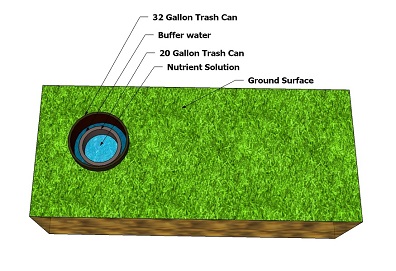

Once

you have placed the reservoir inside the larger container, fill the

reservoir with nutrient solution (or water to pre-test the setup). Then

fill the larger 32 gallon container with water (buffer water) at

least half way or just past where the water level in the reservoir (20

gallon trash can) is. You may need to place a heavy rock in the

reservoir (20 gallon trash can), because if the water level is higher

in the 32 gallon trash can the 20 gallon one might want to float

a little.

The water in the 32 gallon trash can (buffer water)

takes up the air space between the two containers, effectively

continuing direct contact between the ground and the nutrient

reservoir. This will allow the heat from the nutrient reservoir to be

absorbed into the ground cooling the nutrients. Now, to clean the

reservoir all you need to do is simply empty some of the nutrient

solution out, then lift it out to clean it.

(Note: It would be

advisable to add some bleach or chlorine to the buffer water to keep it

clean and to keep anything from growing in it. But make sure that

surface water like excess rain water run off wont be able to get

inside, otherwise the buffer water could overflow into the

nutrient reservoir and it could kill your plants)

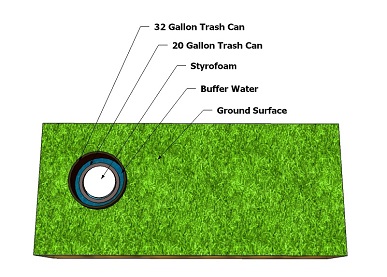

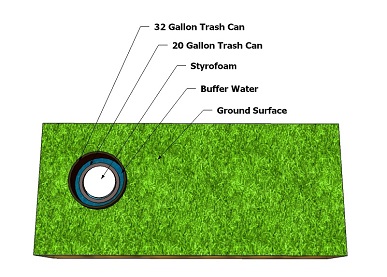

Insulating the top with Styrofoam inserts

Insulating

the top with Styrofoam inserts is quite simple. Cut a circle in a

1 ½ to 2 inch thick sheet of Styrofoam to tightly fit in the 20 gallon

reservoir. Then cut a hole or notch to run the cord and tube for

the pump and cord.

(Note: You can find Styrofoam sheets of different thicknesses in any home improvement store with the home insulation products.)

The

easiest way to cut the Styrofoam is to burn it. I like to use a

inexpensive Soldering iron. You can also heat on end of a metal coat

hanger. The Styrofoam will cut like butter and the heat will leave a

sealed clean edge on the Styrofoam all at the same time.

Now

cut a second piece of the same 1 ½ to 2 inch sheet of Styrofoam in a

circle. This time cut it to tightly fit the larger 32 gallon trash can.

This will help insulate the nutrient solution, but more importantly

insulate the buffer water from surface heat.

(Note: cutting a notch at the edge of the Styrofoam inserts instead of a hole will make maintenance easier)

Now,

cut a hole or notch for the pump tube and cord in the second Styrofoam

insert. Place the second Styrofoam insert in and push it all the

way down to the top of the 20 gallon trash can.

(Note: You may also want to add a handle to the Styrofoam inserts to make taking them out easier.)

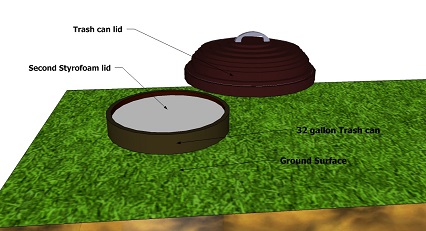

Now

that you have the Styrofoam inserts in place you can mark then cut

where you want to place the nutrient solution return line/tube. Then

mark and make the necessary feed and return line holes/notches in the

32 gallon trash can lid. Place the trash can lid on top and run the

feed and return lines to your Hydroponic system.

(Note: Make

sure you insulate all tubes and hoses that are above ground to keep

them from getting hot and heating your nutrient solution as it flows

through them. If at all possible you should insulate the growing

chambers (plants root zone) to keep them from heating up also.)

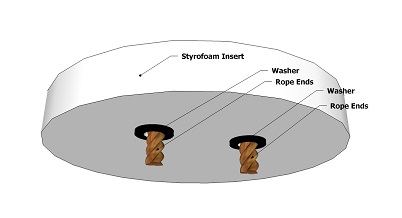

Styrofoam insert handle

From

my own experience making a handle for the Styrofoam inserts will make

taking them out much easier, in turn making the maintenance of your

hydroponic systems much easier. Styrofoam is a week material so you

wont be able to screw a handle into it, and gluing one to it wont last

long either. I wanted to add this page about adding a handle to your

Styrofoam inserts to give you some ideas on how to do this.

Because

the Styrofoam is a week material you should not try to attach anything

to the top of it, because it will just tear off and not last. The best

way to attach the handle is through the Styrofoam inserts and from the

bottom. This way the piece is lifted from the thickest part of the

Styrofoam all at the same time.

First find a piece of rope to

use as the handle then make 2 holes in the Styrofoam inserts, barley

large enough to fit the rope through. Once the rope is through the

holes you will need a support for the rope or it will just tear through

the Styrofoam as you pull it up.

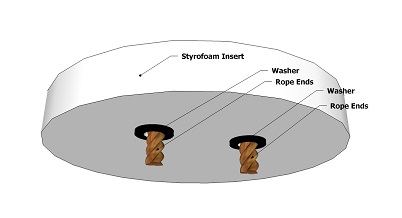

One

way to create the support for the rope is to use large washers (the

larger the more support). Simply place the washers in place over the

holes and glue to the Styrofoam using a waterproof glue, then thread

one end of the rope through each hole and tie both ends of the rope in

a knot to keep it from coming back out. If the holes in the Styrofoam

are not tight agents the rope fill the space with silicone or

waterproof glue to make it stronger and keep any air from going through

the open space.

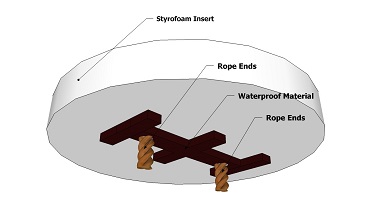

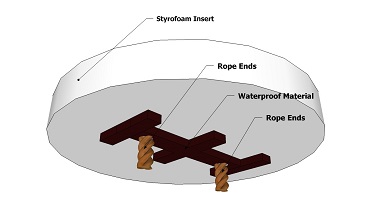

Another even more sturdy support is pictured to

the right. It consists of the same basic idea, but offers more

surface area

contact

with the Styrofoam for more support while lifting it. Like with the

example pictured above glue the support to the Styrofoam using a

waterproof glue. Then thread one end of the rope through one hole, and

the other end through the other hole, then tie a knot in both the

ends of the rope.

If the holes in the Styrofoam are not tight

agents the rope fill the space with silicone or waterproof glue to make

it stronger and keep any air from going through the open space.